Greenhouse gas emissions through our value chain

Scope 1 and 2

Operational emissions

Total emissions

912,000

Tonnes CO2e/year

Contributors to Corteva's greenhouse gas emissions:

Scope 1 - Direct emissions

Scope 2 - Indirect emissions

Scope 3

Upstream and downstream emissions

Total emissions

5,451,000

Tonnes CO2e/year

Contributors to Corteva's greenhouse gas emissions:

Scope 3 - Indirect emissions

- Purchased goods and services

- Parent & commercial seed acres not under Corteva's operational control

- Capital goods

- Fuel- and energy-related emissions not in Scope 1 and 2

- Upstream and downstream transportation and distribution

- Waste generated in operations

- Business travel

- Employee commuting

We are recalibrating our Scope 3 strategy to meet stakeholder needs.

For our Crop Protection business, we now use an activity-based emissions reporting approach for about 20% of our commodity spend and prioritize collecting data from key suppliers, while using average data for others. Our internal analysis shows that even if 1,000 of our top suppliers cut their emissions by 20%, it would only reduce our total Scope 3 emissions by about 1%. Therefore, while we continue to improve our reporting reliability and require our suppliers to act responsibly toward the environment under our Supplier Code of Conduct, we currently do not have a plan to establish a Scope 3 target.

We remain committed to reducing our Scope 1 and 2 GHG emissions; however, our greatest impact will continue to come from developing next-generation seed and crop protection solutions.

Sustainably advantaged and differentiated seed and crop protection products can enable farmers to produce more crops with lower carbon intensity.

→ Learn more about our journey to demonstrate the benefits of new lower-carbon technologies and see Measuring the Environmental Life Cycle Assessments (LCA) of our products

Learn how innovative agricultural solutions are transforming the way we approach farming, offering powerful tools to avoid on-farm emissions.

Our portfolio includes solutions that help farmers adapt to climate changes and decrease on-farm emissions.

For example, Utrisha™ N is a biostimulant that improves nutrient use efficiency and provides supplemental nitrogen directly to plants to support plant health and increase yield potential.

We recently completed a single-impact life cycle assessment, which compares the product carbon footprint of producing corn in Europe with and without the use of Utrisha N. The assessment showed a potential savings of >400,000 tonnes of CO2e over four years.1 That is equal to about 40% of Corteva’s total Scope 1 and 2 GHG emissions.

More convenient weed control

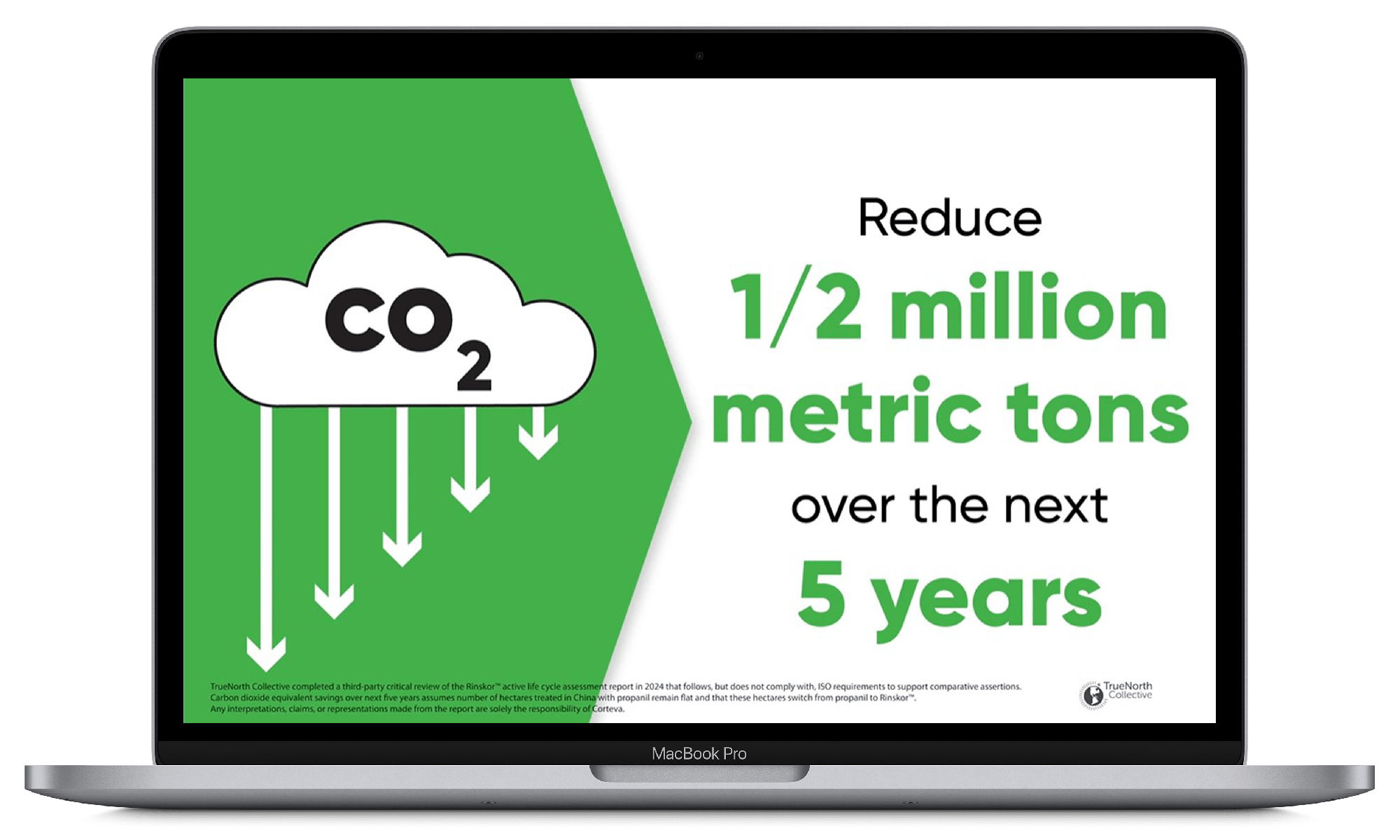

Crop protection products containing Rinskor active help farmers safeguard their crops, and with its low use rate, they don’t need to handle as much product as with other herbicides.

Economic benefit

Mitigates weed resistance with a differentiated mode of action

Biodiversity benefit

Mitigates weeds, preserves desirable vegetation

Climate benefit

150x lower use rate, resulting in emissions savings of 500,000 MT CO2e over five years

CO2e savings potential based on a recently completed single-impact LCA comparing the use of Rinskor™ to propanil on rice in China.

- Preliminary LCA results indicate potential for advantaged corn product carbon footprint with the use of Utrisha N from 2025-2028. These results are based on a yield meta-analysis of corn trials in Europe.

We intend to meet our Scope 1 and 2 target through operational efficiencies and renewable energy strategies across our sites, including:

Renewable Energy Certificates (RECs)

Purchasing high-quality RECs is an important part of our Scope 2 reduction strategy. In 2024, we purchased 60,000 MWh of RECs, which reduced our Scope 2 GHG emissions by about 40,000 tonnes.

Solar power opportunities

Additionally, we continue to identify suitable seed operation sites for potential solar panel installations, partnering with providers to supply power directly through purchase agreements. For example, in 2024, we completed the installation of a new solar panel system at our seed operations facility in Paine, Chile. This project aims to generate ~475 MWh per year for an annual saving of $50,000 and a reduction of about 200 tonnes CO2e.

Also, at our Delmas, South Africa site, we are using solar power to minimize grid electricity needs and for battery back-up during power disruptions, generating over 60 MWh of solar power annually. This system is built to give 4 to 5 hours of power support to avoid generator use during loadshedding (grid-induced power outages or reduction in power supply during peak usage times to prevent the grid from overloading). The site pulls electricity from solar first, then from the grid.

Site sustainability programs

In 2024, we formally launched a sustainability program at our Midland manufacturing site in Michigan, US, as part of our Scope 1 and 2 reduction efforts. The program focuses on reducing energy use, improving efficiency, and cutting waste.

We continue to make progress at a second Michigan site in Harbor Beach. Fundamental engineering interventions are creating energy reduction opportunities with cost and GHG savings. For example, replacing damaged steam traps will save over 57,000 MMBtus of natural gas annually, equivalent to emissions of about 3,000 tonnes CO2e. Additionally, we will save another 9,500 MMBtus of natural gas per year (equivalent to about 500 tonnes CO2e) by adding insulated jackets. And, by partnering with local utilities, the Harbor Beach site received financial incentives for LED lighting upgrades, steam trap replacements, and steam trap insulating jackets in 2024.

What’s next for our climate focus area?

Looking ahead, we expect to implement more renewable energy programs and identify additional energy reduction opportunities. We will continue to conduct Life Cycle Assessments (LCAs) on crop protection products coming through our innovation pipeline, while supporting pragmatic, industry-wide GHG standards and accounting practices.